The Festo Authorized and Certified Training, (FACT) Centre being established at the Caribbean Maritime University will revolutionize the way engineers, technicians and persons working or seeking to work in Engineering and related fields are trained in the Caribbean.

The FACT Centre combines the power of two renowned brands – German firm Festo Didactic – and the internationally accredited Caribbean Maritime University, the first local university to be established at the international level!

The CMU Fact Centre will be the largest in the world, firmly establishing CMU as the institution with the largest cutting-edge engineering training capacity in the region. The FACT centre will allow for a range of training programmes not just catering to new state-of-the-art and Engineering degrees in areas such as Automation and Mechatronics but allow industry certification for new and existing workers who can do shorter courses (modules).

This means the CMU will not just be training the engineers of the future but re-equipping workers with skills for the fourth industrial revolution.

The decisive element of FACT is that the Caribbean Maritime University in Kingston is authorized by Festo to offer expertise and know-how to the free market under the Festo brand. Either for students – called Training for Employability or the Industry – called Training for Productivity.

Director's Message

At CMU we are very proud to say that we have the largest FESTO Authorized and Certified Training Centre in the world. In our FACT Centre we have, at the moment eight laboratories in which we can provide training on topics related to the foundations of Mechatronics to Industry 4.0. Each laboratory has industrial equipment with cutting-edge technology that allows us to meet the training demands of our customers.

With all this technological power we want to collaborate in the improvement of the productivity of industrial companies and we wish to cooperate in the employability of the new generations of Jamaica, the Caribbean, the Americas and why not the entire world?

We have a wide range of standard training, we are continuously designing new training programmes according to the needs of the market and we are also prepared to develop training tailored to the needs of our customers. The rapid technological changes in the industry demand people with a new way of thinking and with a wide range of skills and knowledge that are capable of understanding the technologies in the current and future industry. Undoubtedly, we are specialists in the training of Industrial Automation & Mechatronics.

At CMU you will find everything you need to prepare for the Fourth Industrial Revolution. Give us the opportunity to meet and serve you!

CMU's FACT Centre is the benchmark in the region for industrial training.

CMU’s family welcomes you in advance!

Director's Profile

Education

• Bachelor’s degree in Mechanical Engineering

• Authorized & Certified Trainer by FESTO in the fields of Pneumatics, Electro-Pneumatics, Hydraulics, PLC Programming, Lab Design, Stepper Motors & Servo Motors for Industrial Training since 2008

• Technical and pedagogical training in Mexico, Guatemala, El Salvador, Honduras, Colombia and Germany

Work Experience

• Logistical and technical support in the installation and commissioning of the FACT Centres in El Salvador (2), Uruguay, and Costa Rica (Centre of Excellence)

• Member of the implementation team of the ITCA FEPADE El Salvador Dual Education System for all careers, mainly the Bachelor’s degree in Mechatronics, from 2008 to 2012

• Director of MEGATEC Centre, Zacatecoluca, La Paz, El Salvador – ITCA FEPADE Administration, from 2012 to 2017

The Partnership: The CMU & FESTO

The CMU is a global institution with global reach and a global outlook. We are continuously re-imaging success through increased synergetic alliances, upgrade of technological resources and acquisition of additional ones and producing globally-conscious, industry-ready disciplined leaders.

To serve our students and other stakeholders, efficiently and completely, we invest in technology and inspire innovation at every level of operation. As a result, CMU is the Simulation hub of the Caribbean hosting the largest suite of state-of the-art training simulators, a centre for research and consultancy in renewable energy and the largest and most sophisticated FACT Centre in the world.

The latter is a German engineering turnkey solution that provides world class training and global certification in mechatronics, automation, pneumatics and other industrial globally relevant specializations.

Because our training is highly flexible and responds to your needs, we are able to offer services to a range of groups such as:

• Machine operators

• Set-up personal of production system

• Maintenance & Repair personnel

• Research & Development personnel

• Students from several faculties

• All sectors of industrial production

What is FESTO?

Festo Automation Group

• Worldwide leader in Factory and Process Automation

• Founded in 1925 and still family owned up to now

• Headquarter in Esslingen, Germany

• At present 61 branches worldwide

• Currently over 18,500 employees worldwide

• At present more than 2,800 patents

• Investment into research around 8.5% of total turnover

• Turn-over 3.0 Billion Euro

• More than 300,000 customers in 179 countries

Festo Didactic: the training company

• Market leader in professional educational solutions

• Learning systems in Factory and Process Automation

• Learning systems in Electrical and Electronic Engineering

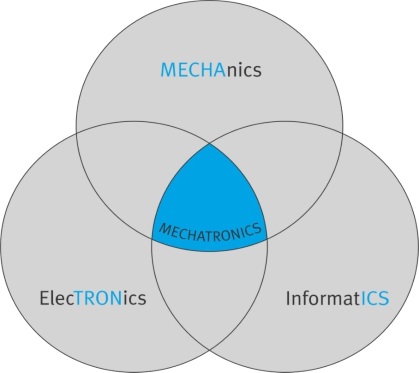

• Holistic solutions for the entire range of Mechatronics

• Seminar provider with 45,000 participants per year

• Educational consulting for complete training centres

• In-house consulting for companies and organizations

• Sponsor partner for WorldSkills

Why Mechatronics?

Mechatronics is a new way of thinking about automated and networked systems, to enable factory and process automation.

Why Automation?

Increase productivity by making higher quality products in less time and at lower cost.

Factory Automation

The handling of solid work-pieces throughout the entire manufacturing process; in each step of the process the shape, dimension, orientation and material is known.

Process Automation

The control of flowing materials (fluids) such as liquids, gases, pourable solids (e.g. powdery material) for automated processes i.e. production, transportation, treatment and waste disposal. Process automation combines automation and process engineering. Mostly closed loop controllers are used within the Process Technology.

Degree Programmes

Bachelor of Engineering in Industrial Automation

• Minimum of five (5) CSEC/GCE O-Level or international equivalent subjects.

• Subjects must include Mathematics, English and two (2) technical science subjects.

• 4-year programme

Bachelor of Engineering in Mechatronics

• Minimum of five (5) CSEC/GCE O-Level or international equivalent subjects.

• Subjects must include Mathematics, English and two (2) technical science subjects.

• 4-year programme

Short Training Programmes

Pneumatics

Fluidics, by means of Pneumatics and Hydraulics, are very essential technologies in the industrial reality. Air is clean, fast, easy to transport and store only to mention some of the many advantages of Pneumatics. All-important topics in Pneumatics and Electro-Pneumatics up to closed loop control can be worked-out in this lab.

Training Modules:

• Pneumatic basics

• Electro-Pneumatic basics

• Electro-Pneumatic advanced

Hydraulics

Wherever high pressure and high force is required in the industry, Hydraulics is providing the solution. All basic aspects of Hydraulics and Electro-Hydraulics can be worked out in this lab.

Training Modules:

• Hydraulic basics

• Electro-Hydraulic basics

• Electro-Hydraulic advanced

Electrics & Industrial Drives

Electrics/Electronics and Industrial Drives are very essential technologies in the industrial reality. Especially to fully understand all combined electrical applications like wiring, sensorics, electrical control of Pneumatics, Hydraulics as well as Industrial Drives including frequency conversion of AC-motors we have to work-out the basics first.

Training Modules:

• Electric basics

• Motor control basics

• AC-motor advanced

Fully Automated System

Fully automated system as the top level of Mechatronics representing the combination of Factory and Process Automation manufacturing and the packaging process. In so many industries both important parts of industrial manufacturing are combined to a fully automated material and signal flow.

Training Modules:

• PLC programming basics

• PLC programming intermediate

• PLC programming advanced

• Industrial communication

• SCADA – Touch Panel application

• Commissioning and Trouble Shooting

• Process Automation basics

Resources

FACT Centre Training Plan

The Training Plan contains detailed information on the courses we offer.

FACT Centre Flyer

The Brochure gives a brief introduction the F.A.C.T. Centre

FACT Centre Image Brochure

The Image Brochure offers a visual exploration of the F.A.C.T. Centre

FACT Centre Virtual Web Page

The Virtual Web Page is an interactive PowerPoint presentation on the F.A.C.T. Centre

FACT Centre Video Presentation

The Virtual Web Page is an interactive PowerPoint presentation on the F.A.C.T. Centre

News

Festo Lab: Another First for Jamaica (Jamaicans.com, October 2018)

Bipartisanship made Festo Training Centre a reality – Holness (Loop Jamaica, September 2018)

FACT Centre for Industrial Automation and Mechatronics Kingston, Jamaica (FESTO Didactic, 2018)

CMU Opens Fact Centre (Jamaica Information Service, September 2018)

CMU's FACT Centre To Boost Jamaica's Automobile Assembly Industry (Jamaica Gleaner, September 2018)

We’ve come a long way…(Caribbean Shipping Association [Website Article] , February 2018)

We’ve come a long way…(Caribbean Shipping Association [Magazine Layout Link], January 2018)

Seeding the Future (American Caribbean Maritime Foundation)

$400-million Festo Centre for CMI (Jamaica Observer, November 2016)